Inside an old warehouse in Amsterdam, currently buzzing with construction crews, test machines, and bursts of creative chaos, a quiet revolution is reshaping how we make shoes.

The company behind it? What The Future. A radically inventive design and technology lab focused on sustainable manufacturing. At the helm is Carrie Howe, former Olympic sailor, now Managing Director & CEO, whose unique combination of strategic precision and athlete’s mindset powers the team’s bold rethinking of how products are made.

“The Olympian’s mindset is the rock,” Carrie says. “What I took with me from my sports career isn’t the medals, it’s the resilience, the growth, the drive. That’s what shapes how I lead, how I problem-solve, and how I build teams that can take on really complex, systemic challenges.”

With a background in high-performance sport and a sharp ability to navigate complexity with a strategy to ask the right questions and listen, Carrie brings a rare mix of vision and execution to the table, and it shows. We met with her for a tour of the still-under-construction space to see firsthand what happens when you throw out the rulebook and start building the future from scratch.

The future of footwear isn’t arriving on a polished showroom floor. It’s emerging in a space still finding its shape: an industrial warehouse mid-renovation, with temporary lights rigged across exposed beams, machines humming under ladders, and tools scattered next to fresh rubber samples. It’s scrappy, loud, and intensely alive.

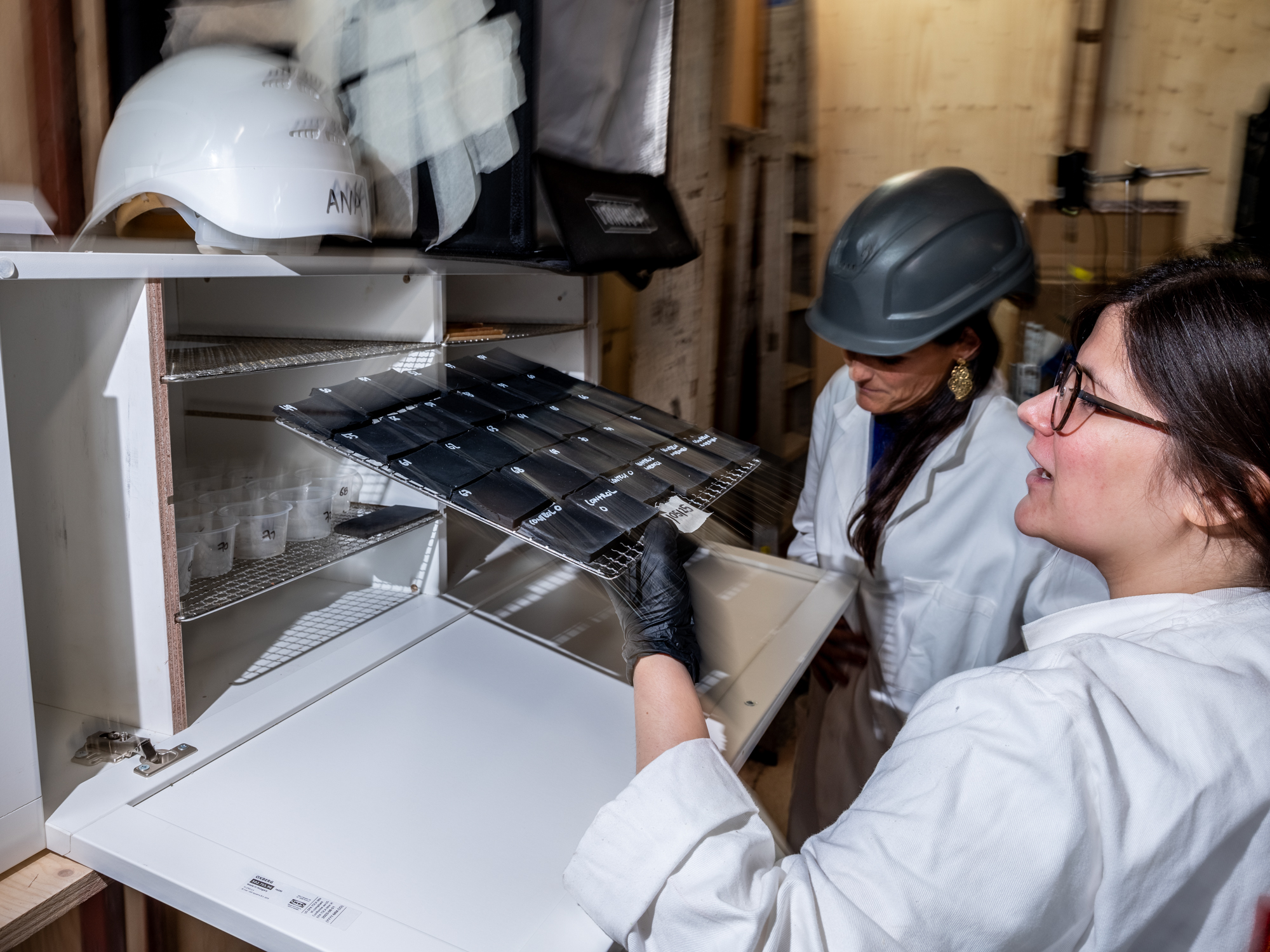

At the heart of What The Future is a team of designers, engineers, and material nerds who are doing something that sounds almost improbable: turning a food-packaging machine into a shoe factory.

Not just any machine, one designed to churn out plastic containers for supermarket ham. Today, it’s doing something far more interesting. It’s making sneakers.Molded Overnight, Not Months

Molded Overnight, Not Months

The traditional footwear industry is rigid, and expensive. Steel molds, aluminum tools, huge production runs, and lead times measured in months. Want to prototype a new sole? The Left and right, in all sizes? That’ll be €200,000, minimum.

Here, that same mold costs €15 in materials and is 3D printed overnight using recycled ABS plastic.

Instead of carving molds from solid metal, this team thermoforms plastic sheets, a technique borrowed from the packaging world, using heat and pressure. Then, they pair it with 3D-printed inserts for full flexibility. One day it’s kids’ sizes, the next it’s men’s streetwear. No tooling changes, no waste, no delay, just a smooth and easily adaptable process.

They’ve even hacked in modularity: quick-swappable molds mean they can test, iterate, and shift on the fly, something the legacy industry can barely imagine.

Straight from the Tree

That wasn’t enough, What The Future also looked at the material going into these molds, and adapted it just as radical. Most shoe soles are made with either synthetic rubber or petroleum based chemicals, fossil-fuel-based, highly processed, and shipped in solid forms that need further energy-intensive molding.

But these soles start as liquid latex. Pure, natural rubber tapped directly from trees grown in biodiverse forests, not monocultures. Liquid poured into a mold and then added a minimal amount of vulcanizing agent during the injection to cross link the polymer chains to transform the rubber from a sticky material into a durable elastomer. This blended with natural additives to match and beat industry needs regarding abrasion, slip resistance and cost.

But What The Future has cracked the code, developing a system that works at scale, with minimal waste, and maximum flexibility.

“It’s a happy material,” says founder Carrie Howe. “The tree wants to give it. The forest thrives. And when the shoe’s done, it decomposes.”

Bye, Glue.

Here’s a dirty little secret of footwear: gluing a sole to an upper is toxic, labor-intensive, and bad for everyone who is in touch with it. A process of sanding, priming, layering, pressing, all done by hand, all releasing fumes, all prone to failure.

This team’s solution? Skip glue entirely.

They inject the liquid rubber directly onto the textile upper, where it bonds mechanically. The fibers absorb the rubber as it cures, creating a strong, flexible hold without any adhesives. It’s patented, durable, and surprisingly beautiful, a seamless merge of sole and upper that cuts labor, cuts emissions, and cuts time.

Not Just Sustainable, But Also Repairable

Repairability isn’t an afterthought here. It’s part of the DNA. As Everything is modular, everything is made to come apart, to be replaced, to go another round. They’ve even prototyped children’s shoes where outgrown soles can be swapped, and baby teething products made from the same clean rubber.

And it’s not theoretical, they’re already working with major brands, showing them how to make shoes that can actually be repaired, reused, and disassembled. Not retrofitted for repair, built for it. And that, in this industry, is revolutionary.

A Workshop in Motion

The lab feels more like a collective of creatives, scientists and dreamers, than a company. One corner holds a prototype lab, another a shelf of test soles and kid-sized samples. There are rebound tests, tensile tests, sandpaper abrasion machines. Some are handmade. Some are hacked together. All are in active use. It's not chaos, it’s motion.

"We’re not trying to beat China," one of the co-founders says. "They’ve optimized mass production with robotics and investment. We’re showing a different path, smaller, smarter, local."

The results speak for themselves: a thousand pairs produced in a week, with just a few hours of machine time each day. Clean processes, fewer hands, better materials and more control. And all in a space where a power drill hums in the background and natural rubber samples dry on a window ledge.

A System Built with Purpose, From Molecule to Mission

What’s perhaps most remarkable is how nothing has been left to chance. Every element, from the recycled plastic used in temporary molds to the labor conditions on rubber plantations, has been considered with care and intention. The team hasn’t just designed a better shoe; they’ve rethought the entire lifecycle, from forest to foot to end-of-life. Even offcuts are collected, shredded, and reused. Even the pigments are scrutinized.

This isn’t sustainability as a selling point, it’s a system-wide ethic. Every choice, every material, every machine modification tells the same story: a future where doing better isn't an afterthought, it's the foundation.

Shoes, Yes, But Also Systems

What’s really being built here isn’t just a better shoe, it’s a better system.

A system that allows for local production. That uses circular materials from known sources. That skips the subcontractor chaos. That puts brands, and even consumers, closer to the materials and processes that shape their products.

And maybe, more than anything, a system that believes beautiful design doesn’t have to come at the planet’s expense.

Because in this under-construction Amsterdam workshop, surrounded by noise and dust and wild ideas, one thing is already very clear:

The future isn’t glued together. It’s molded, and ready to move.

What is What The Future?

What the Future creates breakthrough batch-to-mass manufacturing technologies that enable planet-friendly industrial scale production. Helping manufacturers realize the untapped possibilities of engineering, digital design and 3D technology to minimize production cost, business risk, and environmental impact.