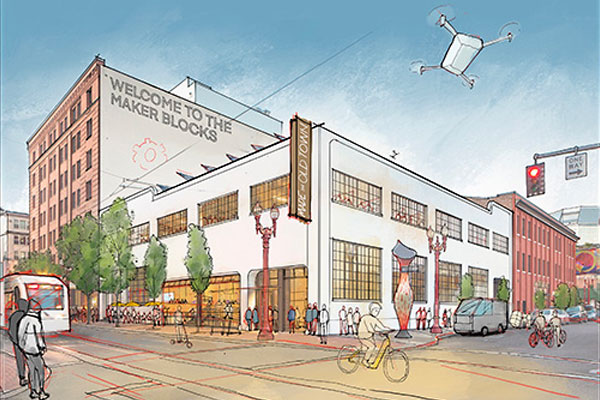

Portland, Oregon, has long been known as the world's footwear and apparel capital, and another initiative is taking that reputation a step further. Made in Old Town is a $125 million redevelopment project in the city's historic Old Town Chinatown that is due to turn nine buildings and over 323,000 square feet into a world-class innovation campus for footwear design.

Image source: Travis Dang, Sera Architects

Where industry and innovation meet

At the core of Made in Old Town is the Footwear and Apparel Manufacturing Innovation (FAMI) Hub, which opened in late 2024. This is a 110,000-square-foot facility that serves as a prototyping and sample-making space for brands and designers, pushing the boundaries of technical, aesthetic, and environmentally friendly innovation.

The ones in charge of this project are some of the most influential names in the industry— Noel Kinder, the former Nike Chief sustainability officer, Eric Liedtke, ex-Adidas President, and Elias Stahl, CEO of Hilos which is a leader in zero-waste 3D printed footwear. Together, they are shaping a space designed for collaboration, innovation, and climate-conscious production. "We are very focused on brands and suppliers that are invested in making an impact," says Noel Kinder, former Nike CSO.

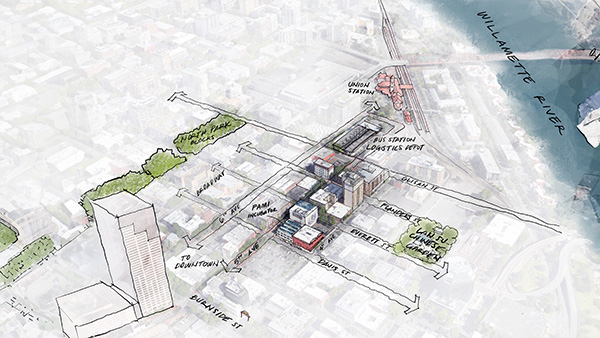

The Campus

Made In Old Town's campus is structured into three core floors, each designed to advance innovation and connect each component of the production process.

The Hub: A prototyping space where members can rapidly transform ideas into samples.

The Tower: A vertical ecosystem for suppliers, researchers, and brand teams. This is a space for meetings, office and showcasing spaces.

The Engine: A finished goods manufacturing space equipped to support local, scalable production with special tax and tariff programs.

Together, these spaces form a closed-loop campus where design, development, and delivery can happen under one roof, which eliminates the need for global shipping, thus reducing carbon emissions.

Additionally, the campus has been designed to support low-waste, local production methods that drastically reduce the carbon footprint of traditional footwear and apparel manufacturing. Brands working within the hub can experiment with circular materials, zero-waste production technologies and small-batch manufacturing.

Image source: Travis Dang, Sera Architectspa

Empowering the local community

The project is owned by the Old Town Purpose Trust, which ensures that the neighbourhood benefits directly from the initiative. Out of the total space, 80,000 square feet will be dedicated to advanced manufacturing, while 110,000 square feet will provide workforce housing to combine economic development with fair access.

The programs on campus include workforce training, internship opportunities, and cultural events designed to strengthen the relationship with Portland residents and small businesses. Through this model, Old Town welcomes not just brands and suppliers but the broader actors involved in the footwear and apparel industry, thereby prioritizing economic resilience.

Image source: Travis Dang, Sera Architects

As cities worldwide are searching for ways to future-proof their industries, Made in Old Town serves as a working model to tackle this challenge.

Want to learn more about this kind of footwear design lab — including ones here in Europe? Then be sure to check out our Reflawn News for more stories like this!

What is Made in Old Town?

Made in Old Town is a $125 million redevelopment project transforming nine historic buildings in Portland’s Old Town Chinatown into a world-class innovation campus for sustainable footwear and apparel design, prototyping, and manufacturing.

How sustainable is the Made in Old Town project?

Made in Old Town promotes local, low-waste, and small-batch manufacturing to reduce the carbon emissions that are associated with footwear production. The campus supports circular materials, zero-waste technologies (like 3D printing), and domestic supply chains to minimize emissions.

.png&w=3840&q=100)

.png&w=3840&q=75)

.jpg&w=3840&q=75)