What if garments could be composted, recycled, and even reprinted into something entirely new? These are the questions that are already being answered by the material science company Balena.

Balena is using 3D printing and bio-based innovation to bring circular fashion closer to reality. Its breakthrough lies in its BioCir®flex3D. A flexible, durable, and fully compostable material developed for 3D printing. And yes, it is the same one used by Stella McCartney's S-Wave Sport Trainer.

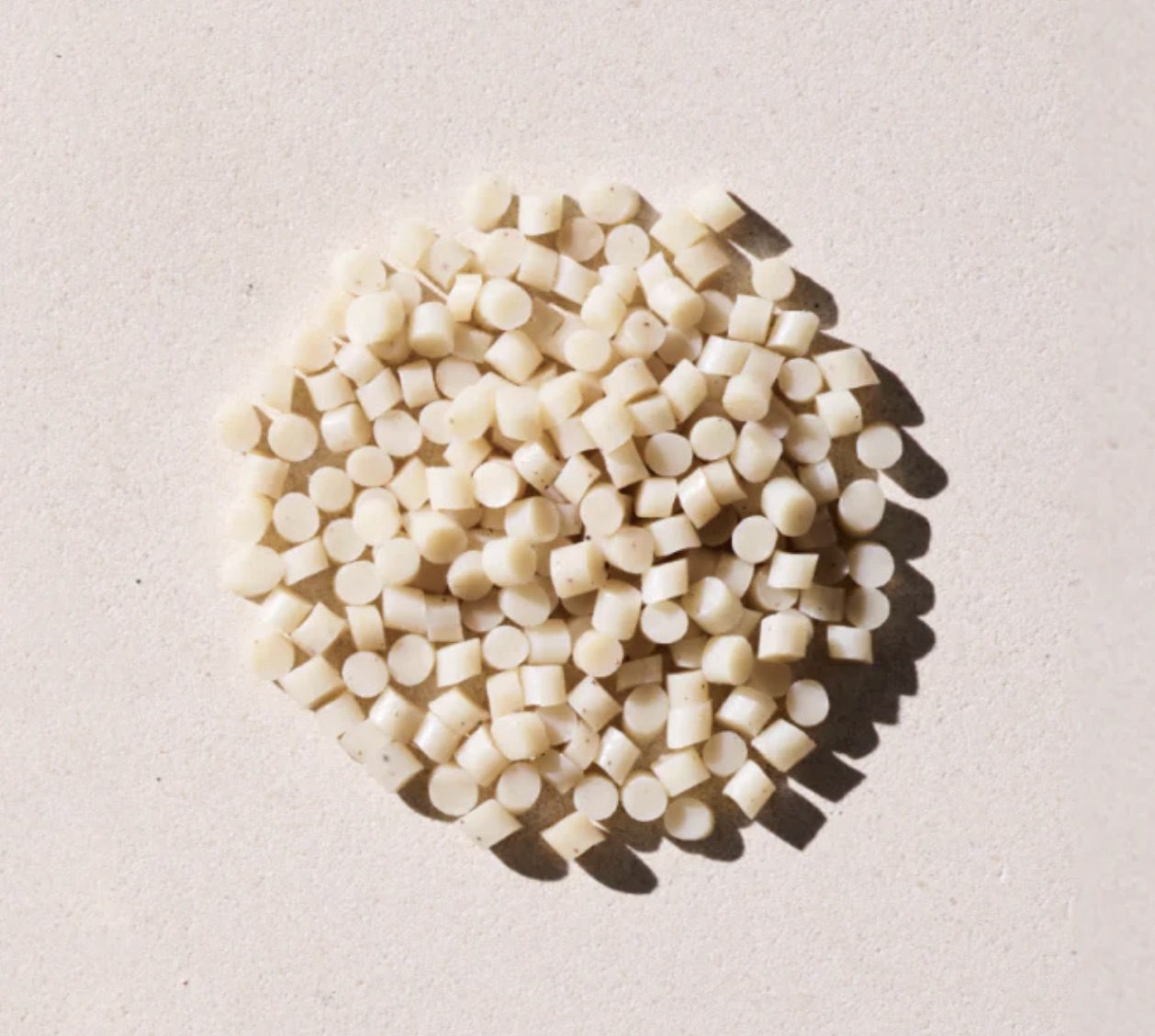

This filament is made from castor beans, polysaccharides, and biodegradable polymers, designed to mimic the stretch and strength of rubber.

While most 3D-printed fashion has stayed in the realm of accessories or stiff, structured pieces, BioCirflex3D changes the game. Its flexibility and wearability make it suitable for ready-to-wear designs, not just exhibitions.

Circular Fashion in Practice

In collaboration with Dutch modular fashion designer Variable Seams, Balena debuted a fully 3D-printed, compostable outfit at Dutch Design Week 2024. The ensemble is made up of 686 individually printed pieces, including a crop top and trousers that can be disassembled for repair or returned to the earth via industrial composting.

This collaboration is an example that Balena's system supports both recycling and biodegradation. Offering brands a choice in how to close the loop.

How it Works

Print: BioCirflex3D is compatible with universally available FDM 3D printers, enabling scalable and local production.

Wear: The garments are strong, comfortable, and resilient. Suitable for daily use.

Recycle or Compost: Items can be returned to Balena's partner network to be either reprinted or biodegraded.

This approach allows for on-demand, zero-waste production to be practical.

More Examples

Balena's collaborations keep on growing and surprising.

Their work with designer Bruno Tognin crafted a top that will later be recycled and reprinted into a new design, showcasing how fashion can evolve without waste.

Another initiative is ROOTS. This highlights the regenerative power of compostable materials in fashion and footwear. These items aren’t just biodegradable but break down cleanly without toxic residue.

Why This Matters

Fashion is one of the most polluting industries on the planet, responsible for tonnes of landfill waste and microplastic pollution. Traditional textiles like polyester and nylon are fossil-based and can take centuries to break down.

Balena offers a tangible solution. By developing bio-based, compostable alternatives that don’t sacrifice quality or design, they’re leading the way toward a circular fashion future.

So, can sustainable fashion scale? With innovators like Balena leading the way, it just might...

All Images: Balena

Want more stories like these? Check out Reflawn's news page.

What is BioCir®flex3D made from?

It’s a biobased, rubber-like material made from castor beans and other natural polymers. It’s industrially compostable and recyclable.

How is this different from traditional fashion?

Instead of sewing or cutting fabric, garments are printed on-demand with zero waste. Additionally, they can be returned to Balena’s network for recycling or composting.

.png&w=3840&q=100)

.png&w=3840&q=75)